RM Raymond Mill

Mills Powder Engineering - RM Raymond Mill Manufacturer

Widely applied to various non-flammable and explosive ores with Mohs hardness below 7 and moisture below 6%, such as calcium carbonate, graphite, bentonite, wollastonite, coal dust, granulating slag, coal ash, alumina, zircon sand, quartz sand, gypsum, talc, calcite, limestone, barite, dolomite, granite, kaolin, bauxite, iron oxide red, iron ore, etc.

Working Principle:

The main engine drives the central shaft to rotate through the double-belt combined transmission mechanism, the upper end of the central shaft is connected to the plum blossom holder, the grinding roller and the plum blossom frame are fit together to form a dynamic grinding system and form swing pivot point. When the plum blossom frame is rotating, grinding roller is pressed to the outer grinding ring through the centrifugal force forming a whole set of crushing combination. Grinding roller rotates by friction force while revolving around grinding ring. With a rigorous shovel knife system which located at the front lower place of grinding roller, in the process of operating, the materials are thrown up and fed between grinding roller and grinding ring to form the crushing materials layer, this materials layers are crushed with the extrusion and friction force caused by grinding roller rotation to get the ideal powder fineness.

FEATURE:

1. Grinding machine adopts the mode of ground installation, and the general height is only as half of traditional type. This decrease the need of workshop height, save cost and facilitate machine maintenance.

2. Roller bearing adopts new sealing mode, no need grease injection, prevent powder from entering bearing to reduce the cost of maintenance.

3. Classified Cavity adopts suspension structure which can automatically lift, descend and shift to reduce machine resonance, lower noise and facilitate the machine maintenance.

4. Compared with traditional Raymond mill, our Innovative grinding Loop and grinding roller together with perfect rim Shape occlusion reduce the dropping speed of material passing through grinding area and prolong the grinding time. Combine the function of broad feeding size range and ultra fine grinding of Raymond mill. The product fineness can be up to d90:10um.

5. Classifier is Installed in the mode of revolving arm to avoid resonate with grinding machine and reduce the vibration of machine and noise, also reduce the cost of tools for maintenance. Open mode of maintenance operation is obviously more convenient.

6. Airflow feeding through cyclone type device, input material rise spirally in the cavity of mill and classifier, which is more helpful to separate out coarse particles and reduce the blower power so that the production cost decrease again.

7. The entire System runs under complete negative pressure, so that the working condition is free from dust, and effluent concentration is ≤30mg/m3.

8. Classifier adopted the technology Introduced from a Germany vertical type, and the motor RPM used for same level of particles is only as half of traditional classifier, not only prolong the lifetime of bearing, but also decrease the degree of consuming of classifying impeller to extend the period of change. Classifier is equipped with the structure of secondary air inlet, air grid type air intake mode which is wear-proof. The classifying efficiency increase by 5-20%. By the combined adjustment of frequency conversion and secondary wind, the classifying efficiency can be improved by 5-20%, and the particle size distribution can be more centralized.

9. Medium pressure impulse bag type dust collector is welded under sealed condition, air leakage rate less than 2%, dust-collecting rate up to above 99.99%, dust effluent concentration less than 30mg/m3. Advantage: compact structure, large filtration area, long life span, suitable for superfine powder filtration.

10. Draught fan is high pressure centrifugal type connected to the system and provide airflow power. Guarantee the entire process is operating under negative pressure and no dust leakage.

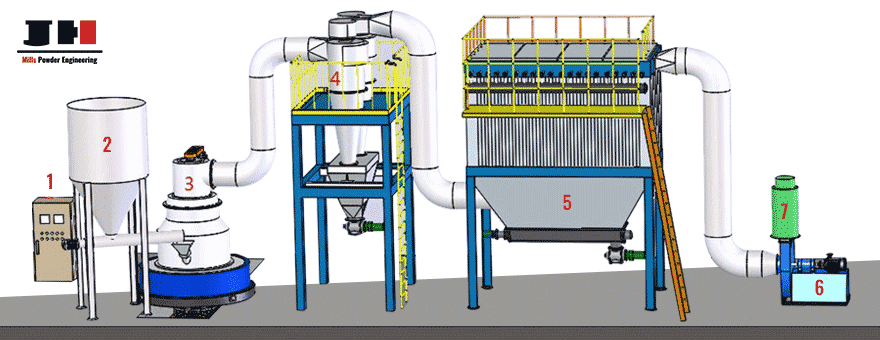

Working Flow Chart:

1. Electric control system

2. Feed system

3. Raymond mill

4. Cyclone collector

5. Dust collector

6. Draught fan

7. Silencer

Technical Parameters:

| Model | 3RM1100 | 4RM1100 | 5RM1400 | 6RM1800 |

| Roller quantity (pc) | 3 | 4 | 5 | 6 |

| Roller size (mm) | Φ270×140 | Φ310×170 | Φ460×240 | Φ550×250 |

| Main power (kw) | 22 | 37 | 90 | 180 |

| RPM (r/min) | 150 | 130 | 103 | 95 |

| Air classifier (kw) | 7.5 | 15 | 22 | 45 |

| Feed size (mm) | 10 | 10 | 15 | 15 |

| Product size (μm) | 10~150 | 10~75 | 5~40 | 3~40 |

| Production capacity (t/h) | 0.5-2 | 0.8~4 | 1~5 | 2~10 |

| Dimension (m) | 4X3X3 | 6X5X3.5 | 8X7X4 | 12X7X4 |