LM Vertical Roller Mill

Mills Powder Engineering - LM Vertical Roller Mill Manufacturer

Widely applied to Calcium carbonate, barite, limestone, calcite, illite, gypsum, pyrophyllite, kaolin, bentonite, sepiolite, potassium ore, aluminum dydroxide, iron oxide red, zirconia, cement, electric power, metallurgy, chemical industry, non-metallic mineral, etc.

Working Principle:

Material is ground on a rotary grinding plate that passes under large rollers, and forced off the grinding plate by centrifugal force, where it is then brought into the high efficiency classifier integrated with the vertical mill by the high-speed upward hot air flow from the nozzle ring (wind ring), the coarse powder is returned to the grinding plate for additional grinding while qualified powder is collected as product. Coarse powder not brought up by hot air flow would drop from the wind ring, after scraped out by scraping plate, they would be conveyed to roller mill by outer elevator for regrinding.

Feature:

1. Adopt material bed rolling, friction and impact as the grinding mechanism, high efficiency, saving 20%-30% power consumption compared with ball mill, low noise and small floor space.

2. Short grinding time, small repeat grinding rate, uniform particle size distribution, stable chemical composition and high quality product.

3. Self-grinding in material bed, avoid the direct contact between the grinding roller and the grinding plate to prevent from vibration, reduce wear, can guarantee the product whiteness and purity.

4. Flexible air spring pressure to adjust the roller, shrink freely, no rebound time, the pressure force is uniform and lasting. Production capacity increases significantly. Compared with traditional pressurized systems, Flexible combination system is more resistant to vibration and compression, and no-load start can be realized.

5. Integration of pulverlizing, grinding, drying and classifying, broad application range, one mill can grind multiple materials.

6. Equipped with spraying device, facilitate to create grinding material bed layer to increase the production capacity.

7. Through oil cylinder rotation arm to turn out roller for easy maintenance, roller shell and roller assembly adopt split taper sleeve tightening and expanding structure, greatly improve the maintenance convenience.

8. Automatic and remote control system to realize unmanned operation.

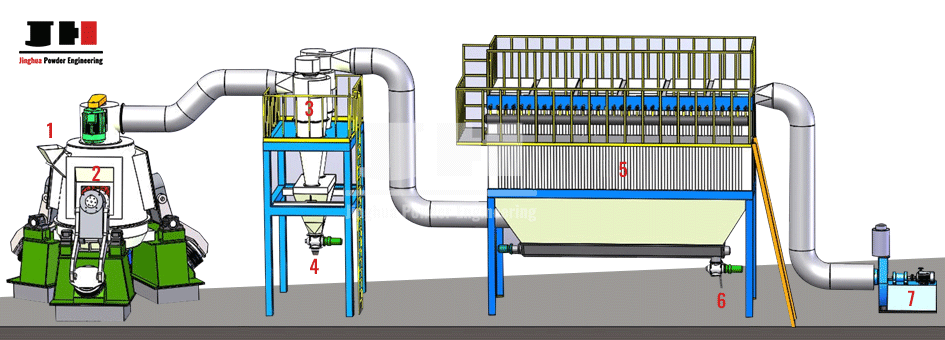

Working Flow Chart:

1. Feeding inlet

2. Vertical mill

3. Cyclone collector

4. Discharge outlet

5. Dust collector

6. Discharge outlet

7. Draught fan

Technical Parameters:

Technical Parameter for coal

| Model | Grinding disc diameter (mm) | Number of roller (pc) | Main power (kw) | Product size (μm) | Production capacity (t/h) |

| LM08 | 800 | 2 | 55 | the passing rate of 75μm is 80% | 3-5 |

| LM11 | 1100 | 2 | 110 | 6-8 | |

| LM13 | 1300 | 3 | 200 | 10-15 | |

| LM19 | 1900 | 3 | 400 | 26-35 | |

| LM22 | 2200 | 3 | 560 | 40-55 | |

| LM24 | 2400 | 3 | 710 | 60-75 |

Technical Parameter for slag

| Model | Grinding disc diameter (mm) | Number of roller (pc) | Main power (kw) | Specific surface area | Production capacity (t/h) |

| LM19 | 1900 | 3 | 500 | ≥420㎡/kg | 12-14 |

| LM22 | 2200 | 3 | 800 | 20-24 | |

| LM24 | 2400 | 3 | 1200 | 30-35 |

Technical Parameter for non-metallic mineral

| Model | Grinding disc diameter (mm) | Number of roller (pc) | Main power (kw) | Product size (μm) | Production capacity (t/h) |

| LM08 | 800 | 2 | 55 | D97=10-40μm | 0.8-2.5 |

| LM11 | 1100 | 2 | 110 | 1.8-4.5 | |

| LM13 | 1300 | 3 | 200 | 3.5-13 | |

| LM19 | 1900 | 3 | 400 | 6.5-24 | |

| LM22 | 2200 | 3 | 560 | 8-30 | |

| LM24 | 2400 | 3 | 710 | 12-38 |

Technical Parameter for flue gas desulphurization

| Model | Grinding disc diameter (mm) | Number of roller (pc) | Main power (kw) | Product size (μm) | Production capacity (t/h) |

| LM08 | 800 | 2 | 55 | D90~D95=45μm | 3-5 |

| LM11 | 1100 | 2 | 110 | 7-13 | |

| LM13 | 1300 | 3 | 200 | 10-16 | |

| LM19 | 1900 | 3 | 400 | 23-32 | |

| LM22 | 2200 | 3 | 500 | 30-42 | |

| LM24 | 2400 | 3 | 630 | 38-50 |