AF Air Classifier

Mills Powder Engineering - AF Air Classifier Manufacturer

Widely applied to calcium carbonate, kaolin, quartz, talc, mica, zircon sand, feldspar, chemical, metallurgy, abrasive, ceramic, medicine, pesticide, food, health products, new material, refractory material, etc.

Working Principle:

The classifier and cyclone separator, dust collector and draught fan form a classifying system. Under the action of fan suction and inertial forces, the material is moved from the lower inlet of the classifier to the classifying zone with the ascending airflow. Under the strong centrifugal force generated by the high-speed rotating of classifying wheel, the materials are separated and the fine particles which meet size requirements through the classifier impeller gap into the cyclone separator and the dust collector, the coarse particles entrained part of the fine particles collided with the wall and the velocity disappeared, descending along the cylinder wall to the secondary air outlet, and the coarse and fine particles were separated by the strong washing action of the secondary air. The fine particles rise to the classifying zone for secondary classifying, and the coarse particles fall to the discharge port for discharging.

Feature:

1. Optimized impeller structure design of vertical single rotor and horizontal multi-rotor, which can be in conjunction with ball mill, table roller mill and Raymond mill to form closed circulation, using multi-stage technology to improve product fineness and increase capacity.

2. Classifying efficiency can be 60-90%, d97=2. 0 ~150um is adjustable.

3. Designed to the infinitely variable speeds and wear resistant, clean and change varieties of product easily.

4. Negative pressure operation, no dust, low noise and vibration.

5. Eliminate the oversize and superfine particle existing in product, particle size is uniform.

6. In conjunction with multiple classifiers to get different particle sizes.

7. The flammable and explosive, oxidative materials can be classified with inert gas shielding.

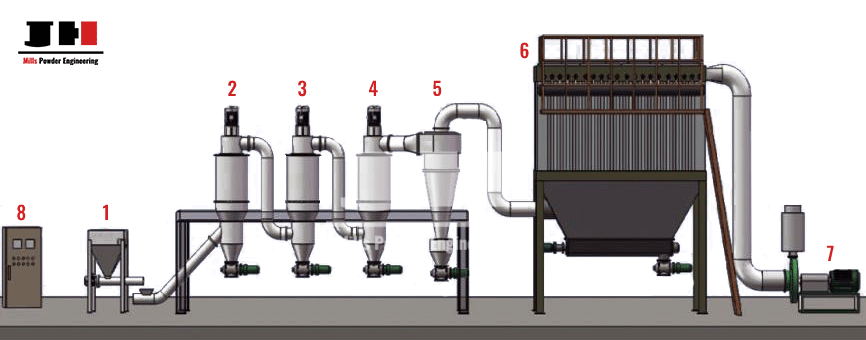

Working Flow Chart:

1. Feeding system

2. Air Classifier 1

3. Air Classifier 2

4. Air Classifier 3

5. Cyclone collector

6. Dust collector

7. Draught fan

8. Electrical control system

Technical Parameters:

Single-rotor

| Model | Production capacity (t/h) | Product size (μm) | Efficiency (%) | Main power (kw) | Installed power (kw) |

| AF050 | 0.1-0.5 | 2-100 | 70-90 | 5.5 | 30 |

| AF100 | 0.5-1.0 | 2-100 | 70-90 | 11 | 45 |

| AF200 | 1.0-3.0 | 2-100 | 70-90 | 22 | 70 |

| AF400 | 2.0-8.0 | 2-100 | 70-90 | 37 | 95 |

| AF600 | 5.0-15 | 2-100 | 70-90 | 45 | 120 |

| AF800 | 10-25 | 2-100 | 70-90 | 55 | 200 |

| AF1000 | 20-50 | 2-100 | 70-90 | 75 | 250 |

| AF1200 | 50-100 | 2-100 | 70-90 | 110 | 360 |

Multi-rotors

| Model | Production capacity (kg/h) | Product size (μm) | Efficiency (%) | Main power (kw) | Air volume (m3/h) |

| AF200-4 | 100-1600 | 2-45 | 70-90 | 7.5×4 | 3400 |

| AF200-6 | 200-2400 | 2-45 | 70-90 | 7.5×6 | 5000 |

| AF315-4 | 300-4000 | 2-45 | 70-90 | 18.5×4 | 9500 |

| AF315-6 | 500-6000 | 2-45 | 70-90 | 18.5×6 | 14000 |

| AF400-4 | 800-5500 | 3-45 | 70-90 | 22×4 | 13500 |

| AF400-6 | 1200-8000 | 3-45 | 70-90 | 22×6 | 20000 |

| AF500-4 | 1500-10000 | 5-45 | 70-90 | 30×4 | 21000 |

| AF500-6 | 2200-150000 | 5-45 | 70-90 | 30×6 | 31000 |