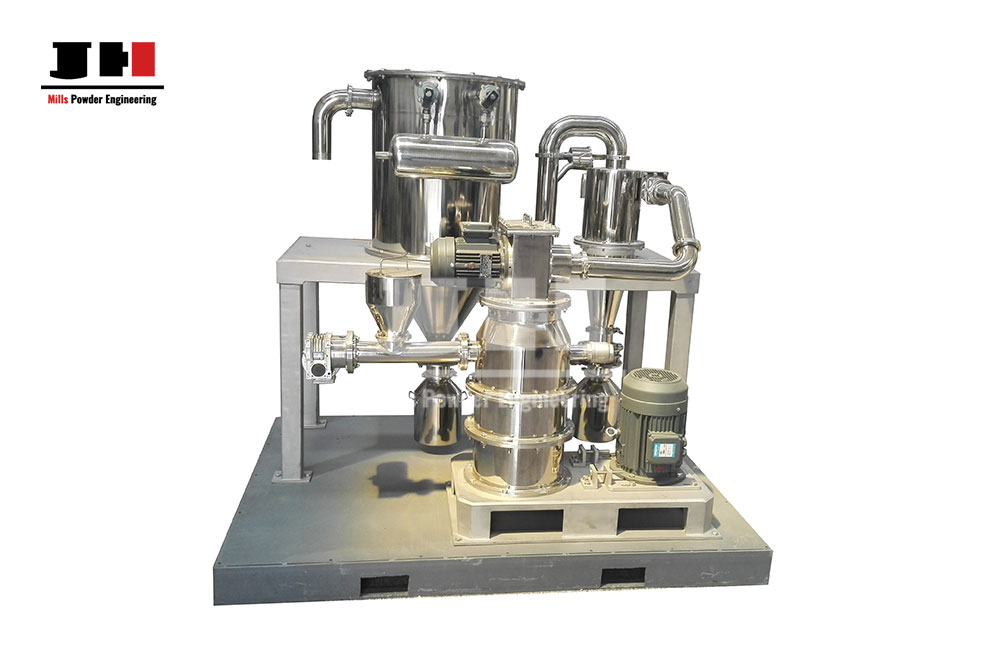

Impact mill CR200

Impact Mill CR200 (Air Classifying Mill)

Especially used for R&D and testing of new products in research institutes, university laboratories and factory laboratories.

Working Principle:

Materials are fed into the grinding chamber by feeding system, they are impacted, sheared and ground by high speed rotary hammers and tooth plate. The ground materials enter into the classifying zone with airflow, the coarse and fine powder are separated through the classifying wheel adjusted by the frequency conversion, qualified powder is collected by the cyclone separator and dust collector, the coarse powder continues to be ground.

Feature:

1. Integration of grinding and classifying, thus avoid over grinding.

2. Speed of classifying wheel is adjustable to obtain ideal particle.

3. Narrow particle size distribution, fineness d97=2~100 micron is adjustable.

4. Inner temperature is reduced by airflow, and grinding chamber is used water cooling jacket for cooling, suitable for heat-sensitive materials.

5. Negative pressure work condition, no dust pollution.

6. Grinder is equipped with slag discharge device, which can automatically discharge the hard and impurity materials.

7. Less wearing parts and easy maintenance.

8. Can be connected with multi-stage classifiers to obtain products with multiple sizes at one time.

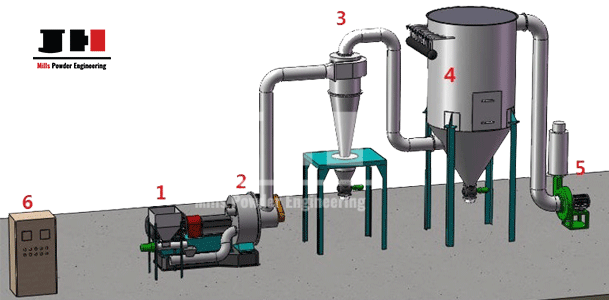

Working Flow Chart:

1. Feeding system

2. Impact mill

3. Cyclone collector

4. Dust collector

5. Draught fan

6. Electrical control system

Technical Parameters:

Model | CR200 |

Rotor diameter (mm) | 140 |

Rotating speed of rotor (r/min) | 4500-5000 |

Feed size (mm) | <15 |

Product size (um) | 2-250 |

Production capacity (Ton/h) | 0.05-0.5 |

Maximum handling air volume (m3/h) | 600 |

Power of main engine (Kw) | 5.5 |

Power of classifier(Kw) | 1.5 |

Power of draught fan (Kw) | 4 |

Outline diameter (L x W x H) (mm) | 1500 x 1900 x 1800 |

Total power of system (Kw) | 11 |

Filtering area of dust collector (m2) | 8.05 |

Pulse-jet Cleaning pressure (Mpa) | 0.4-0.6 |

Air consumption of Pulse-jet Cleaning (m3/min) | 0.2 |