Jet mill

Mills Powder Engineering - Jet Mill Manufacturer

Widely applied to Chemicals, pharmaceuticals, metallurgy, abrasives, non-metallic minerals, battery anode and cathode materials, talc, kaolin, quartz, graphite, flame retardant, ceramics, pigments and food additives, etc.

Working Principle:

Compressed air after cooling, filtering and drying is sprayed into grinding chamber at high speed through Laval nozzles, at the intersection of multiple high pressure airflow, the material would be repeatedly collided, rubbed, sheared and finally be ground. The ground materials would move to the built-in classifying zone with the ascending airflow. Under the action of centrifugal force generated by high-speed rotating of classifying wheel, coarse powder and fine powder would be separated. Qualified fine powder would be collected by cyclone separator and dust collector, while coarse powder would drop to the grinding chamber to be ground again.

Feature:

1. Superfine and uniform particle size and fineness can be D97=2micron.

2. Build-in turbo classifying wheel can avoid over grinding.

3. No excess heat is produced during grinding, especially suitable for materials of heat sensitivity and low melting point.

4. The grinding process is completed by the collision of the materials themselves, fully self-grinding, so the device is durable and the purity of products is high.

5. No rotating device in grinding section, no wear and low noise.

6. Compact structure, easy installation and dismantlement

7. Heat-sensitive, inflammable and explosive materials can be ground with inert gases which can be recycling use.

8. Can be connected with multi-stage classifiers to obtain products with multiple sizes at one time, the particle size distribution is narrow and centralized.

9. PLC control system, easy operation.

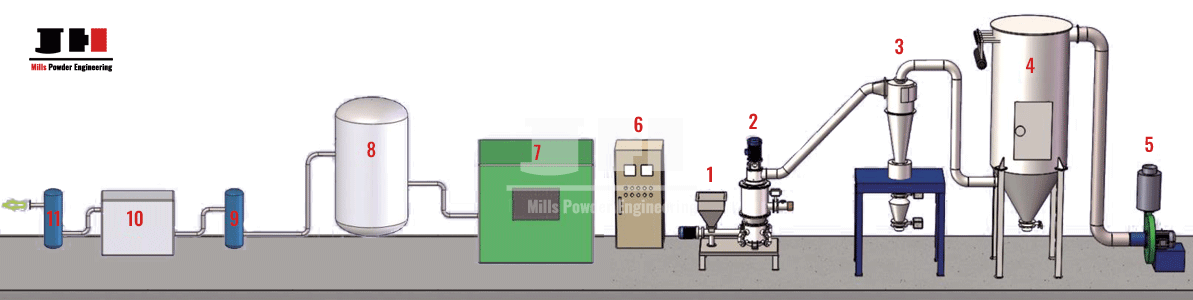

Working Flow Chart:

1. Feeding system

2. Jet mill

3. Cyclone collector

4. Dust collector

5. Draught fan

6. Electrical control system

7. Air compressor

8. Air storage tank

9. Rough filter

10. Air cooling drier

11. Precise filter

Technical Parameters:

| Model | AB03 | AB06 | AB10 | AB15 | AB20 | AB30 | AB40 | AB60 | AB80 |

| Production capacity (kg/h) | 10-100 | 20-250 | 60-500 | 150-800 | 200-1200 | 300-1800 | 400-2500 | 600-3500 | 1000-5000 |

| Air consumption (m3/min) | 3 | 6 | 10 | 15 | 20 | 30 | 40 | 60 | 80 |

| Feed size (mm) | <2 | <2 | <2 | <2 | <2 | <2 | <2 | <2 | <2 |

| Product size (μm) | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 |

| Installed power (kw) | 30 | 50 | 90 | 110 | 150 | 220 | 300 | 450 | 580 |